Overview

T&C Ice Company is a commercial ice manufacturing and distribution facility in a moderately soft water area. They where experiencing scale build-up particularly in the condensers/heat exchangers and ice machine tubes. This was being dealt with by taking machines out of operation periodically to manually descale and clean the system. The company was interested in alternative methods of scale removal and prevention in order to increase production time.

Key Problems

After discussion with the owner, the key problem areas identified were:

- Condensers/heat exchangers had to be taken off-line on a regular basis for descaling. A high head pressure and increasing temperatures indicated that the condensers had to be descaled.

- Hard water scale decreased ice production and would degrade the equipment if not taken care of promptly

- Ice machine tubes and related equipment were scaling over time, resulting in slower freezing times and ice sticking to the tubes which could potentially damage the long ice tubes due to the ice expanding.

- Increased head pressure resulting in a reduction in ice production of up to 20%

- Failure of the o-rings in the recirculating pumps due to use of descale chemicals

Water Analysis

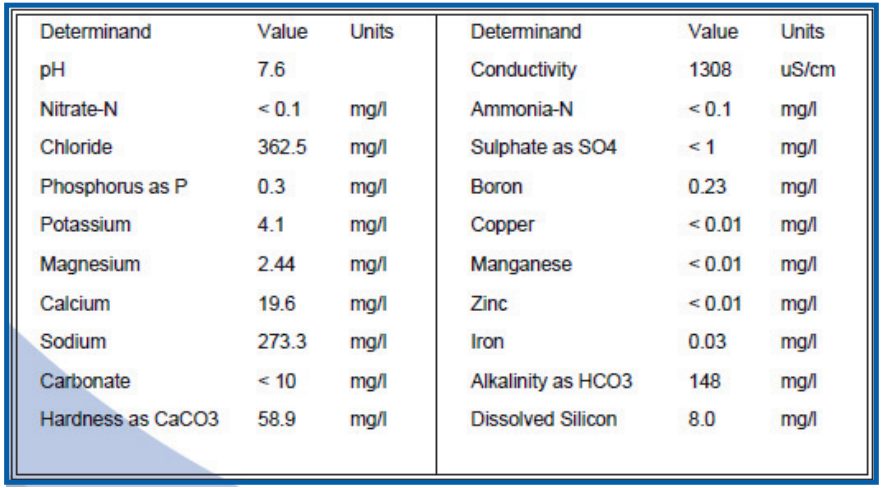

A water analysis test was taken from the site and gave a result of 58.9mg/l hardness as CaCO3

Our Solution

One Integro™ 2 v3 system was installed on the main water line coming into the building covering seven ice machines as well as the #1 condenser. Additionally, after a few months, it was decided to install another Integro™ 2 v3 system on the closed loop serving condenser #5 and #6. This provided a comparison between the #1 condenser and associated ice machines which only receive one pass of water through the Integro™ system from the main water line compared with condensers #5 and #6 which are continuously circulating water through the Integro™ system via the closed loop water circuit. The closed loop is topped up with water from the mainline from time-to-time.

The Results

The Integro™ systems removed historical scale build-up in the condensers which the owner observed when he opened the condenser plates on December 20, 2020, March 1, 2021 and December 30, 2021. Further observational findings were:

- Ice machines had not required manual descaling since Integro™ installation.

- Increase in ice production.

- Scale build-up on the condensers was visibly reduced and no rodding out of condenser tubes has been required since installation of the Sidon Integro™ units.

- Running temperature of the condensers has improved significantly.

- Head pressure on the condensers has been kept within the normal operating ranges.

Summary

Since the two Integro™ 2 v3 systems were installed there has been a significant reduction in the scale buildup inside the condensers/heat exchanger tubes with no new scale formation. The condensers have been operating at a normal operating pressure and have not had to be taken down due to the head pressure increasing, as was the case in the past. None of the condensers have needed to be ‘rodded out’ since installation of the technology.

Additionally, the seven ice machines have all been operating efficiently with no scale build up inside the ice tubes. The machines have not been running ‘hot’ so ice production time has been consistent and the compressors are not having to work as hard.

Installation of the Integro™ technology has improved operating efficiency, reduced down time, decreased scheduled maintenance and improved production output.

What the Owners had to say?

“Head pressure on the condensers is down. It has stayed consistent. Never got near having to take it down. So going on since 9/20/20 and no need to rod any out in 2020 ,2021 or2022. Something is working if the head pressure is not going sky high, because the water I’ve got [is very hard and] has a good bit of scale in it. Since the compressors are not running as hard, I am making more ice on the machines. If the head pressure goes up, it can cut my production 10% to 20% easy because it will slow you down. Normally, I was cleaning my ice machines twice a year. I haven’t done it at all since installing the Integro systems. I haven’t even cleaned them out due to scale in over a year. Additionally, I haven’t lost a pump since installing the Integro whereas before the descaler would start killing the o-rings.

Owner, T & C Ice Company, Mississippi, USA