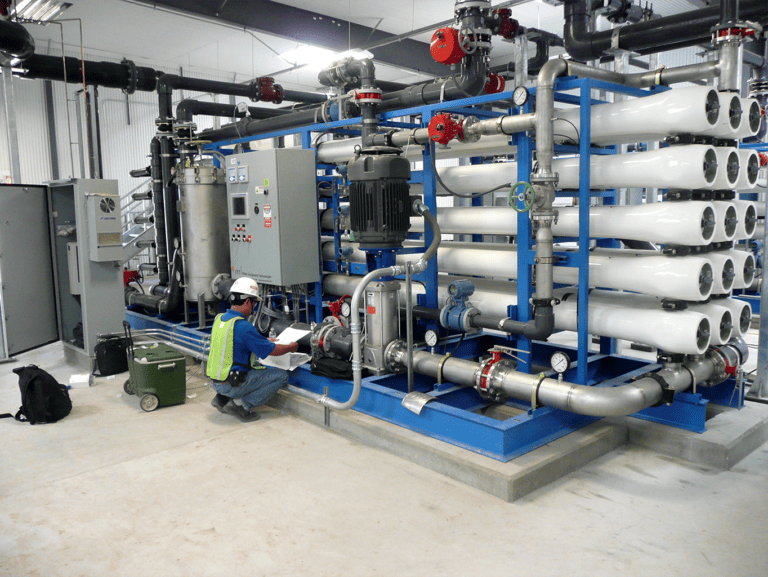

Solutions for RO & Desalinisation Efficiency

Reduce energy costs, enhance efficiency, reduce maintenance, and extend membrane life with chemical-free water restructuring.

Overcoming Challenges in Reverse Osmosis and Desalination

Reverse osmosis (RO) and seawater desalination systems are essential for providing clean, potable water. However, they face significant efficiency challenges, including:

-

- Limescale and mineral deposits that clog membranes and reduce water flow.

- High energy consumption due to increased pressure requirements.

- Biofouling and corrosion, leading to costly maintenance and reduced system lifespan.

- Frequent chemical treatments, which increase operational costs and environmental impact.

Traditional solutions rely on chemical additives and extensive pre-treatment methods, which can be expensive and unsustainable. Sidon Water’s Integro™ Technology offers a game-changing alternative.

Integro™ Technology: A Sustainable Solution For Reverse Osmosis

Further information how the IntegroTM works can be found here

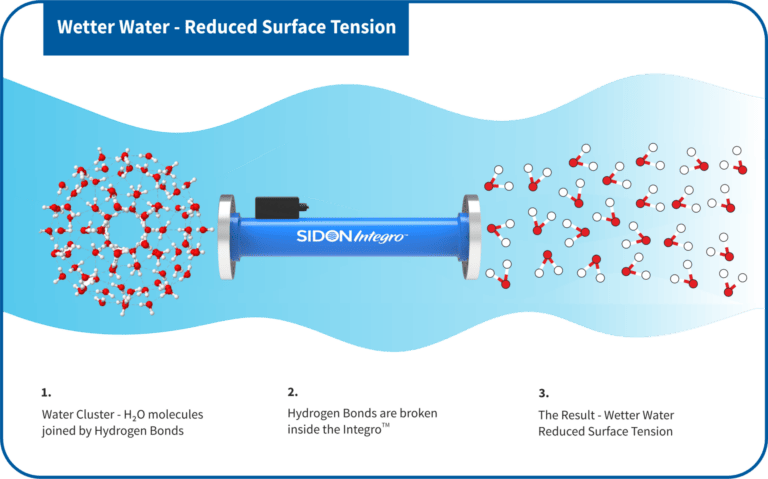

Integro™ Technology enhances RO and desalination efficiency by introducing additional electrons into the water upstream of the filtration system. This innovative process prevents scale formation, dissolves existing deposits, and disrupts bacterial biofilms—all without requiring harsh chemicals.

How It Works:

-

- Prevents Limescale Formation: The technology neutralises scale-forming ions (such as Ca²⁺ and Mg²⁺), keeping minerals dissolved and preventing them from adhering to membranes.

- Removes Existing Scale Deposits: Disrupts ionic bonds in hardened scale, breaking it down into soluble forms that can be flushed away naturally.

- Reduces Biofouling and Corrosion: By modifying the surface charge of waterborne particles, the system inhibits bacterial adhesion, preventing biofilm development and protecting membranes and pipes from degradation.

- Improves Water Flow and System Efficiency: With cleaner membranes, the system operates at optimal pressure, reducing energy requirements by up to 20%.

Integro™ Technology in Desalination Systems

Seawater desalination presents even greater challenges due to higher concentrations of scale-forming minerals and biofouling risks. The Integro™ Technology is particularly effective in this environment, offering the following benefits:

-

- Prevents Scaling from Seawater Minerals: Inhibits calcium carbonate (CaCO₃), magnesium carbonate (MgCO₃), and sulphate deposits.

- Keeps Silica and Alumina in Suspension: Reduces membrane fouling by preventing these compounds from crystallising.

- Inhibits Bacterial Growth: Disrupts biofilm formation, reducing the need for chemical disinfectants.

- Improves Energy Efficiency: Desalination requires high pressure to overcome osmotic barriers. By keeping membranes clean, Integro™ reduces required pressures, leading to substantial energy savings.

- Extends Membrane Life: Cleaner membranes result in longer operational lifespans, decreasing the frequency of costly replacements.

Recommended Implementation Strategies

1. Pre-Treatment Stage:

-

- Install Integro™ before the media filtration step to neutralise scale-forming ions early.

- Combine with traditional filtration methods for enhanced performance.

- Reduce chemical pre-treatments, lowering costs and environmental impact.

2. RO Membrane Stage:

-

- Place Integro™ before RO membrane feed pumps to prevent scaling on membrane surfaces.

- Monitor system efficiency with post-treatment conductivity and pressure analysis.

3. Post-Treatment Stage (Optional):

-

- Use Integro™ in remineralisation systems to stabilise treated water and prevent post-treatment scaling.

- Apply in brine discharge systems to improve outflow efficiency and minimise environmental impact.

Benefits of Integro™ for RO & Desalinisation Systems:

Higher Water Recovery Rates

By minimising scaling, more water can be processed before reaching concentration limits, increasing efficiency by 5-10%.

Sustainability and Environmental Benefits

The Integro™ Technology is designed to align with modern sustainability goals by reducing chemical use, energy consumption, and waste production:

- Lower Chemical Dependency: By preventing scale naturally, the need for anti-scalants and harsh cleaning agents is significantly reduced.

- Energy Savings: Reducing the pressure required for water flow leads to lower greenhouse gas emissions, particularly in large-scale industrial operations.

- Minimised Waste: Longer membrane life means fewer discarded membranes and less frequent system overhauls, contributing to a more sustainable water purification process.

Companies That Trust Us

Case Studies On Reverse Osmosis

Enhancing Reverse Osmosis Efficiency in a Commercial Laundry

Improving Energy Efficiency and Water Quality at a Modern UK Hotel

Contact Details

- 11777 Bernardo Plaza Ct, Suite 208, San Diego, CA, 92128

- 858-324-2700

- info@sidonwater.com