Plate Heat Exchangers

Limescale leads to reduced efficiency, breakdowns and increased energy consumption. Learn how the IntegroTM can help.

Challenges in Plate Heat Exchanger Performance

Plate heat exchangers play a critical role in various industrial processes, providing efficient heat transfer for heating, cooling, and thermal processing applications.

However, these essential components are susceptible to the detrimental effects of hard water, that can compromise their performance and longevity.

Limescale Build-up:

Hard water minerals, such as calcium and magnesium, can precipitate onto the surface of plate heat exchangers, forming stubborn scale deposits.

Corrosion:

The presence of dissolved minerals in hard water can accelerate corrosion within plate heat exchangers, leading to metal degradation, leaks and premature equipment failure.

Reduced Efficiency:

Scale build-up blocks the flow of water through the plate heat exchangers, reducing overall system performance.

Equipment Damage:

Scaling and corrosion can cause irreversible damage to plate heat exchanger components, resulting in frequent repairs, downtime, and replacement costs.

Increased Energy Use:

Limescale build-up leads to decreased heat transfer efficiency, requiring plate heat exchangers to work harder and consume more energy to maintain desired temperatures.

The Carbon Trust estimates that just 1mm of limescale in heating equipment increases energy consumption by up to 7%, with 6mm increasing consumption by as much as 40%.

How The Integro Solves These Challenges

The IntegroTM applies cutting-edge water treatment technology to remove existing limescale build up and prevent further formation thereby resolving the following issues:

- Fouling and Scaling Prevention: Through physical water conditioning, Integro minimises scale formation and inhibits fouling, ensuring consistent performance.

- Enhanced Energy Efficiency: By maintaining optimal heat transfer surfaces, Integro reduces energy consumption and maximises operational efficiency.

- Extended Equipment Lifespan: The reduction of corrosion and wear extends the longevity of your PHEs, lowering replacement costs.

- Reduced Maintenance: Integro’s proactive approach minimises cleaning requirements, cutting downtime significantly.

What You'll Get:

- Cost-Effective Operation: The Integro™ significantly reduces energy consumption, leading to substantial cost savings over time.

- Improved System Reliability: Reduce downtime and maintenance costs associated with scale-related issues, ensuring reliable operation and productivity.

- Efficient Heat Transfer: Maximize the performance of your plate heat exchangers, ensuring efficient energy utilization and consistent process temperatures.

- Scale Removal & Prevention:The Integro™ effectively prevents the formation of limescale, preserving heat exchanger performance.

- Environmental Responsibility: Reduce your carbon footprint and contribute to sustainable practices with the eco-friendly Integro™ technology.

- Legionella Control: The Integro™ acts an effective secondary control measure for Legionella prevention.

Companies That Trust Us

At Sidon Water, we’re proud to be the trusted partner of forward-thinking companies across a wide range of industries.

Case Studies on Plate Heat Exchangers

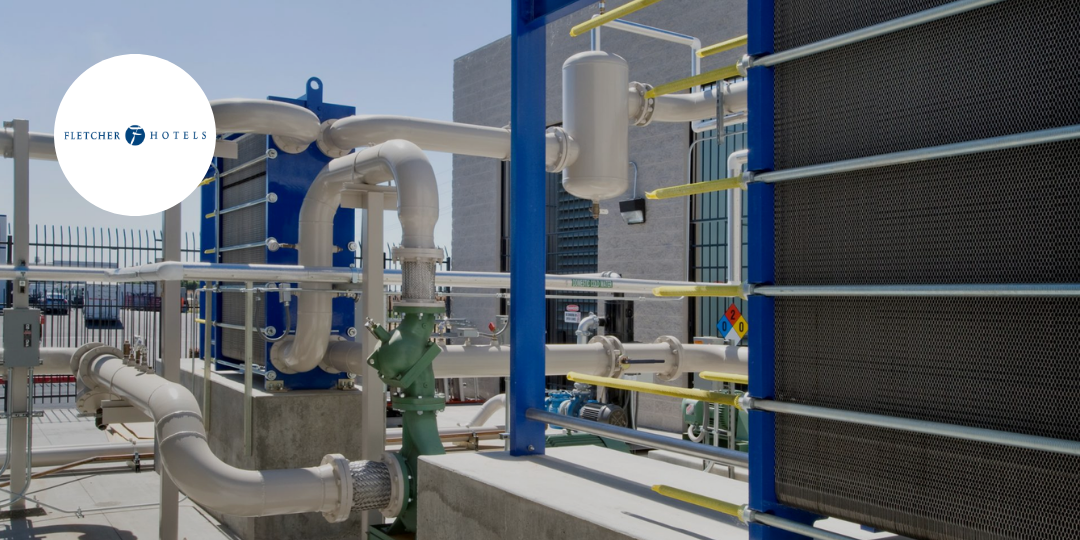

Reducing Scale in Commercial Plate Heat Exchangers Using the Integro™ System

Fletcher Hotels

Solutions We Offer

Discover how our tailored solutions effectively tackle hard water, improve quality, reduce limescale, and promote efficiency and sustainability.

Our Industries

We provide customized water treatment solutions across a wide range of industries from manufacturing to hospitality.